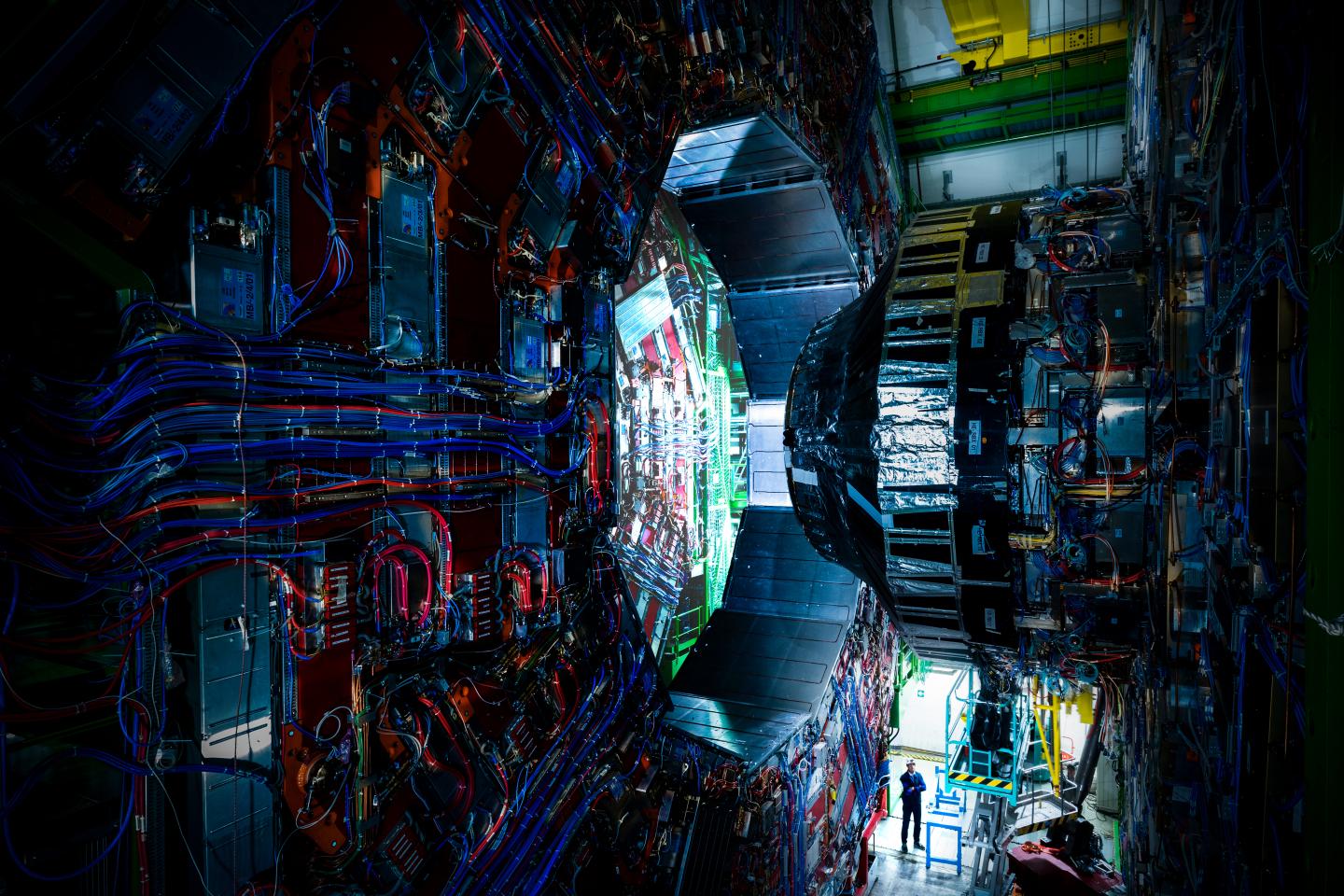

CERN’s knowhow and facilities for end-to-end design, assembly, testing and operation of superconductive magnet systems.

CERN´s Know-How

- Knowhow on applied superconductivity (materials, wires, cables, current leads, transfer lines)

- In-house design and modelling of superconductive devices and magnet systems

- Providing a ‘one-stop-shop’ with access to a range of unique facilities for testing ideas and new innovative magnet / superconductivity concepts

Facts & Figures

- 7600 km: length of superconductive niobium titanium cables used in LHC

- 14.6 T: high field 100 mm aperture superconducting dipole test facility (Fresca2) operating at 1.9 K

- 20 kA: record currents at 20 K with magnesium diboride for power transmission

- 170: tonnes of liquid helium to reach the a temperature of - 271.3 °C

- 9600: extreme numbers of SC magnet systems being operated for decades

- 1232: number of 15 m long dipole magnets, each 28 t in weight

- 392: number of quadrupole magnets to help focus the beam of particles

- 14,6 T: high field 100 mm aperture superconducting dipole test facility (Fresca2) operating at 1.9 K

Value Proposition

Read more about Superconductivity and Magnets here.

Key Competences

Superconducting materials

CERN uses a wide range of superconducting materials in the construction of its accelerators and experiments. Niobium titanium has been the workhorse for the LHC. Nb3Sn is required to produce the high-field magnets needed for the high luminosity upgrade. A wide range of materials are being explored to enable the cables, magnets and devices required for the future.

Magnet design & modelling

CERN has vast experience with magnet design and modelling, with more than 50 types of permanent and superconductive electromagnets to steer particles: dipole magnets, but also complex sextupole, octupole and decapole magnets, which are necessary to guarantee beam stability. On top of this, in the detectors many different magnet types are used. CERN is using an holistic approach to magnet design and uses in-house software tools for fast and accurate simulations.

Assembly and testing

CERN has unique infrastructure for assembly and testing of resistive and superconductive magnet systems. The laboratories provide all infrastructure for manufacturing, assembly and (cyclic) testing of large components at high mechanical stresses, currents, magnetic fields and at low temperatures.

Key Applications

Transporting currents >10kA

The powering of a superconducting system requires transport of high currents, from ambient to cryogenic temperatures, the latter of which is necessary to enable superconductivity. For designing these superconductive devices, CERN has unique design knowhow and prototyping experience, leveraging knowledge of material properties and in-house developed simulation and modelling software.

Protection of Superconductive Devices

Coupling-Loss Induced Quench (CLIQ) is an innovative quench protection method that heats large portions of a superconductor reliably and efficiently. CLIQ’s fast and homogeneous transfer of the coil to the normal state can enable safe magnet operation at energy densities presently not possible with other systems.